In today’s fast-paced manufacturing landscape, innovation isn’t just an advantage—it’s a necessity. Companies are constantly seeking ways to enhance speed, precision, and efficiency. This is where Repmold emerges as a transformative force, reshaping how products move from concept to reality. By blending digital craftsmanship with advanced material science, it offers a powerful solution to modern production challenges.

This technology is not merely an incremental improvement; it signifies a fundamental shift in manufacturing philosophy. By seamlessly bridging the gap between initial design and market-ready products, Repmold empowers businesses to accelerate their innovation cycles and operate with greater agility.

Contents

What is Repmold?

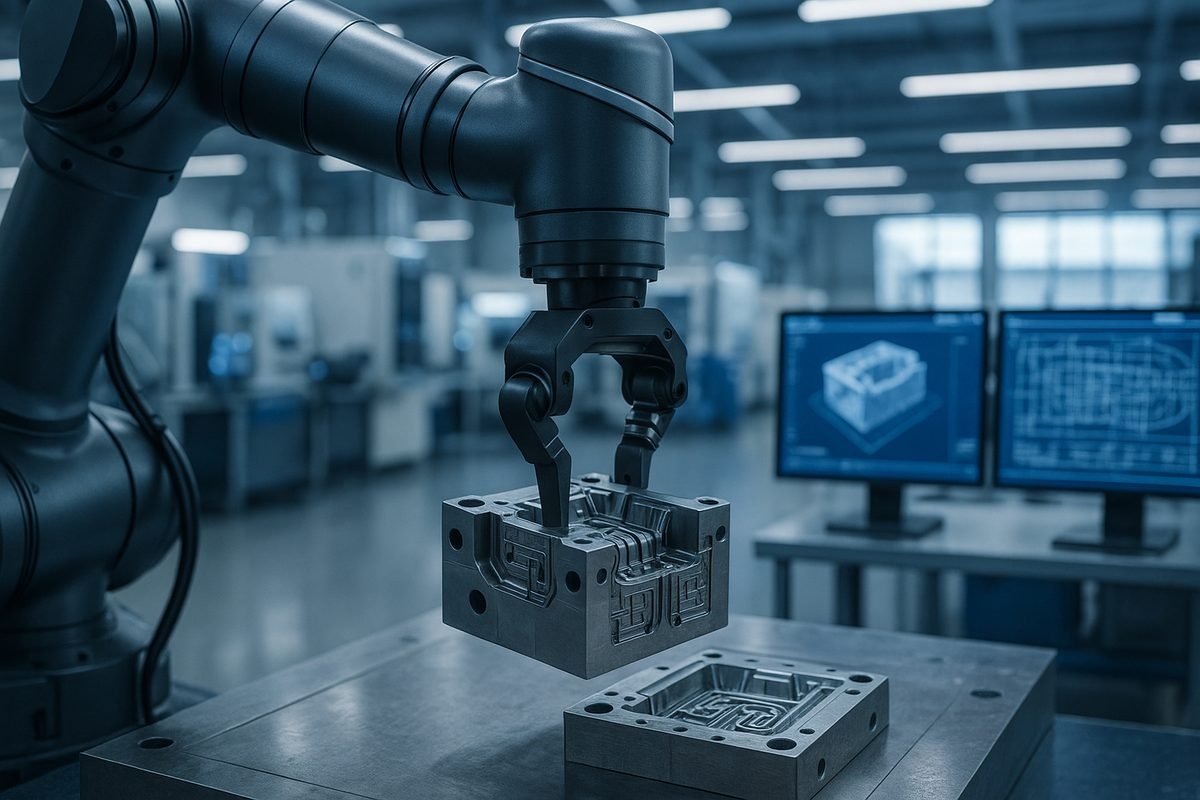

So, what exactly is Repmold? The term stands for replication molding, a sophisticated manufacturing technique that harmonizes digital design with advanced molding processes. The core principle is simple yet powerful: creating high-fidelity replicas from a master pattern. This approach enables the production of intricate parts with an impressive combination of speed and accuracy.

Unlike conventional manufacturing methods that are often plagued by long lead times and prohibitive costs, Repmold streamlines the entire workflow. It offers a flexible and efficient alternative for producing a wide spectrum of components, from functional prototypes to final end-use parts, establishing it as a cornerstone of modern agile manufacturing.

How Does the Repmold Process Work?

The true elegance of the Repmold process is found in its systematic, digitally-driven workflow. It masterfully transforms a digital concept into a tangible product through a series of meticulously defined stages, guaranteeing consistency and quality from start to finish.

The Digital Design Phase

The journey begins with a digital blueprint. Using Computer-Aided Design (CAD) software, engineers craft a precise 3D model of the intended part. This digital-first methodology allows for thorough planning and optimization before any materials are committed, minimizing errors and waste down the line.

Master Pattern and Mold Creation

From this digital model, a master pattern is brought to life, typically through high-resolution 3D printing or precise CNC machining. This pattern acts as the definitive template. A flexible mold, commonly crafted from silicone, is then cast around the master, flawlessly capturing every minute detail and contour of its surface.

The Replication Stage

Once the mold is cured and ready, the replication stage commences. Production-grade materials, such as robust engineering resins or versatile urethanes, are injected into the mold’s cavity. This step is executed under carefully controlled conditions to ensure that every single copy is a perfect, defect-free reproduction of the original master pattern.

Key Advantages of Repmold Technology

The widespread adoption of Repmold technology is no accident. It’s fueled by a clear set of advantages that directly address the most critical challenges in modern manufacturing: the relentless demand for greater speed, lower costs, and uncompromising quality.

Unmatched Speed and Efficiency

Repmold drastically compresses the production timeline. Molds that traditionally required weeks or even months to fabricate can now be created in just a few days. This remarkable acceleration empowers companies to transition from prototyping to full production at a pace that was previously unimaginable.

Significant Cost-Effectiveness

By sidestepping the steep costs of traditional hard tooling, Repmold makes low to mid-volume production runs economically feasible. This democratization of manufacturing opens the door for smaller businesses and innovative startups to compete on a level playing field with larger enterprises, all without the need for massive upfront capital investment.

Superior Precision and Complexity

This innovative technology excels at reproducing parts with highly complex geometries and fine, intricate details that often pose a challenge for conventional methods. The use of flexible, high-resolution molds ensures that even the most ambitious and nuanced designs are replicated with outstanding fidelity.

Repmold’s Transformative Impact Across Industries

The sheer versatility of Repmold has established it as an invaluable tool across a diverse array of sectors. Its capacity to deliver high-quality, production-grade parts on demand is fundamentally transforming how various industries approach both product development and manufacturing.

In the automotive sector, Repmold is instrumental in creating custom interior components and functional prototypes that can withstand rigorous testing. Similarly, the aerospace industry leverages it to produce lightweight yet incredibly durable cabin parts and intricate ductwork, where precision is paramount.

In the medical and healthcare field, Repmold technology is a game-changer, enabling the manufacture of patient-specific surgical guides and custom housings for sophisticated medical devices. For the fast-paced consumer electronics market, it facilitates the rapid iteration of prototypes for device casings, buttons, and other critical components, ensuring a flawless fit and finish before the final commitment to mass production.

The Future of Manufacturing is Here with Repmold

Looking ahead, Repmold is far more than a fleeting trend; it offers a clear glimpse into the future of manufacturing. As the technology continues its rapid evolution, its impact is poised to grow exponentially. The integration of artificial intelligence and machine learning promises to further optimize the Repmold process, unlocking even greater levels of precision and operational efficiency.

Simultaneously, continuous advancements in material science are broadening the horizons for Repmold applications. New polymers and advanced composites are constantly being developed, offering enhanced strength, superior durability, and a host of other specialized properties to meet ever-more-demanding specifications.

Ultimately, Repmold represents a pivotal shift towards a more agile, innovative, and accessible manufacturing paradigm. It empowers creators, engineers, and businesses of all sizes to bring their ideas to life with unprecedented speed and effectiveness. This technology is not just changing the process; it’s heralding a new era of production, defined by creativity and efficiency.